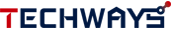

- logiRECORDER System Connections

-

-

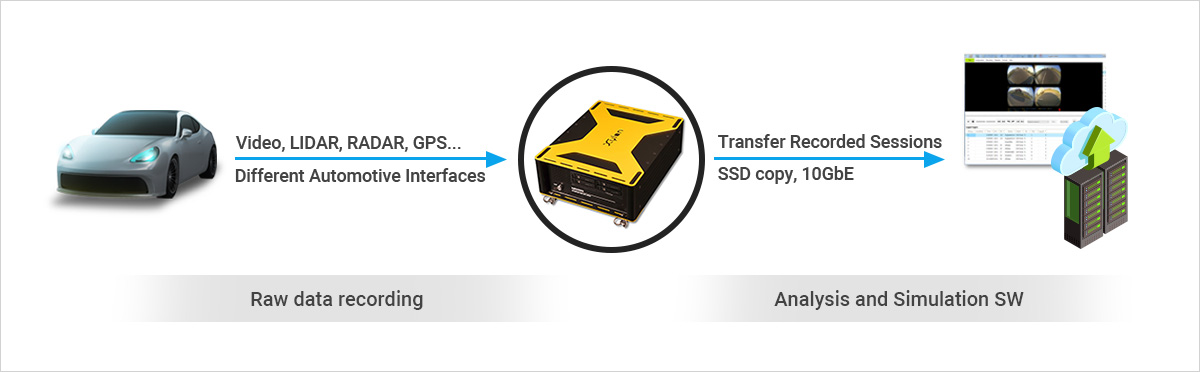

The logiRECORDER Automotive HIL Video Logger inserts between any type of the real vehicle’s camera installation and ECUs to non-intrusively record Terabytes (TB) of multi-channel uncompressed video and network data with low latency. The device integrates separated video inputs and outputs to avoid constant re-cabling and multiple in-vehicle network connectors.

-

Video cameras can be initialized and powered either by Electronic Control Units (ECUs), or by the logiRECORDER data logger itself.

-

The user-friendly logiRECORDER Dashboard application enables hardware configuration, setup of advanced triggers and filters for continuous and event-triggered recordings, parallel playback of video and network data, recorded data manipulation and offline analysis. Aside from the wired Ethernet, the Dashboard can use Wi-Fi for comfortable in-cabin controls of logiRECORDER data loggers placed in a test-vehicle trunk, and the 4G LTE for completely wireless configuration and control of remote test fleets that may be located anywhere in the world.

-

An optional HDMI monitor enables control display output while recording and during playback. The control video is also available within the logiRECORDER Dashboard application, which enables direct video transfers from the test vehicle driving on the other continent!

-

SSD SATA drives handling does not require special copying stations. Off-the-shelf SSD drives, which can be purchased independently from Xylon, can be removed and simply plugged in a PC for easy video and network data transfer.

-

Multiple logiRECORDER units can stack into one logger with more interfaces, data bandwidth and storage space.

-

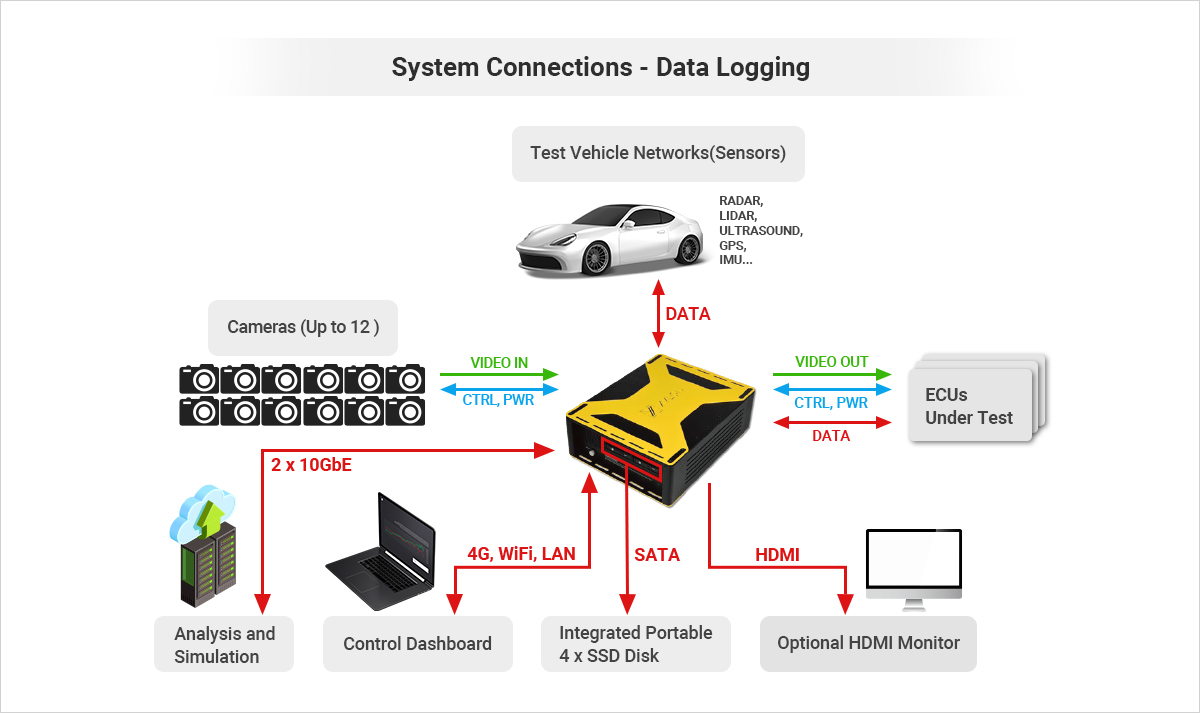

- logiRECORDER Raw Data Logging

-

-

To work around the connectivity issues, and to be able to support various test configurations, many data loggers on the market use fast Ethernet (10 GbE and faster) interfaces and specially designed Measurement Test Units (MTUs) to connect different car sensors.

-

MTUs basically convert the sensor’s native automotive interface, such as Texas Instruments FPD-Link III or GMSL high-speed serial interface from Maxim Integrated, into data packets suitable for Ethernet communications.

-

This data logging approach may be disadvantageous in several ways. MTU development is fairly complex, costly and lengthy, and may raise interoperability issues with equipment from different manufacturers. Aside from mentioned technical and business issues, the harvested data quality may be lowered due to inescapable data conversions.

-

Xylon’s logiRECORDER Automotive HIL Video Logger does not require external MTUs and provides best-in class raw data interfacing through various I/O modules. It is modular and based on programmable FPGA chip technology that enables central timestamping and precise data manipulation out of reach to PC-based data loggers.

-

The current selection of twenty (20) interface I/O modules includes video modules, such as FPD-Link III and next generation GMSL, automotive network modules like CAN and LIN, smart accelerators for e.g. local TAPI parsing, utility and Ethernet module boards. Such a rich selection of boards can support many versatile test configurations, and can be re-used in different testing and validation programs. Furthermore, the flexible hardware platform, which is fully developed and controlled by Xylon, can be easily expanded by new additional modules for new interface types.

-

Within the test car, the logiRECORDER can work in human-operated or self-standing mode. Raw test data is harvested in the industry standard MDF4 or open ROS formats, which enable easy data use in third-party software installations.

-

Sophisticated triggering and filtering options, as well as easily inserted markers, enable precise data refining during test drives.

-

The recordings replicate original sensory data, which is of crucial importance to obtaining the most realistic HIL simulations and tests.

-

- Direct HIL Injection of Raw and/or Synthetic Data

-

-

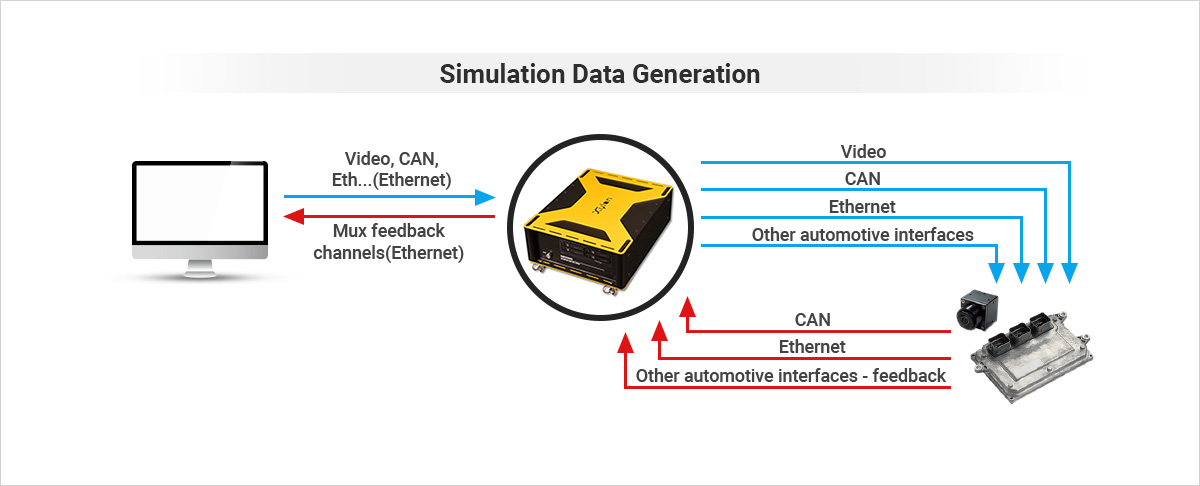

Development and validation of autonomous vehicles and Advanced Driver Assistance Systems (ADAS) are extremely demanding processes that include real-life road testing and exhaustive laboratory-conducted simulations. While real-world road testing is the ultimate step before releasing an automotive product, many companies tend to replace it as much as possible with realistic software and hardware-in-the-loop (HIL) simulations, which are less costly, offer greater controllability, and generally improve test quality and validation coverage.

-

The logiRECORDER Automotive HIL Video Logger is capable of playing back realistically restored recorded sessions, while simultaneously and optionally recording the Device under Test’s (DUT) responses.

-

The logiRECORDER playbacks automotive sensory data in its original form and connects directly to DUT’s through native automotive interfaces. Playback data is electrically and logically formatted to fully correspond with the requirements of internal busses of an operational vehicle driving along the road. In this way, the logiRECORDER efficiently replicates the complete test-vehicle’s multi-camera video system and in-vehicle data busses on a developer’s desk.

-

The logiRECORDER Automotive HIL Video Logger can also inject synthetically generated automotive sensory data. In cooperation with prominent providers of software simulation platforms, Xylon has developed software plug-ins that fetch simulated data and record it in MDF4 data formats, which are suitable for HIL data injection.

-

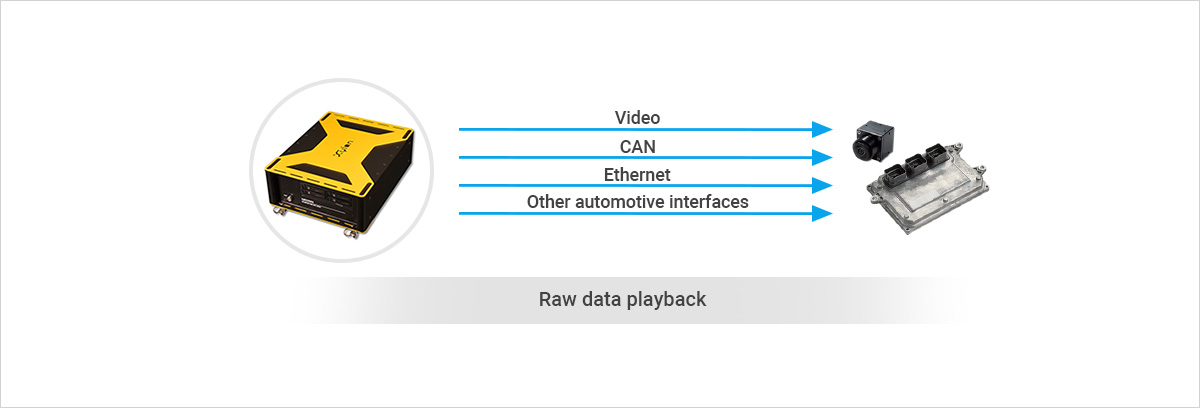

- logiRECORDER Raw Data Playback

-

-

Besides easy road harvesting of unaltered raw data from test vehicles, the logiRECORDER Automotive HIL Video Logger enables realistic playback of recorded sessions – straight out of the same box! The playback is based on recorded time stamps that enable the logger to restore exact timings and signal relations between multi-channel sensory data in real time.

-

The logiRECORDER playbacks automotive sensory data in its original form and connects directly to Electronic Control Units (ECUs) through native automotive interfaces. Playback data is electrically and logically formatted to fully correspond with the requirements of internal busses of an operational vehicle driving along the road. In this way, the logiRECORDER efficiently replicates the complete test-vehicle’s multi-camera video system and in-vehicle data busses on a developer’s desk.

-

This outstanding feature greatly eases R&D and testing in lab environments. For example, a comfortable lab tuning of the computer vision system, fed with the specific driving situation, can be looped as long as needed, with no need for additional test drives.

- Virtual Test Drive

-

-

Today’s most advanced simulation solutions model comprehensive virtual environments with an included driver model, a detailed vehicle model and highly flexible models for roads and traffic. Such modelling environments provide for complete and realistic test scenarios.

-

Virtual test drive environments can additionally improve precision and simulation quality by embedding real hardware components.

-

The essential difference between fully software-based and HIL-supported simulations reflects in the fact that real Electronic Control Units (ECUs) DUT anticipate physical stimuli data, while simultaneously generating responses that are electrically and logically formatted to fully correspond with the requirements of internal busses of an operational vehicle driving along the road.

-

The logiRECORDER Automotive HIL Video Logger can be plugged in virtual test drive environments to repeatedly translate all DUT input and output signals between physical and virtual domains, and to convert them as expected by interfaces of the simulation environment.

-

- In-cabin HIL

-

-

Nowadays emerging in-cabin automotive systems count passengers, guard babies seated in vehicles’ rear seats, check drivers for signs of drowsiness and ensure that they are alert and ready to take over vehicle controls.

-

Xylon’s logiRECORDER Automotive HIL Video Logger has been recognized and used by several Tier1s and OEMs as a flexible tool suitable for all stages of development and validation of in-cabin monitoring systems. Experience gain through that cooperation has been additionally expanded thanks to internal development of Xylon’s ARTIEYE® Driver Monitoring Technology Suite.

-

Xylon’s HIL-capable data logger device supports.

-

Time synchronized data recording of precisely timestamped data from all application relevant sensors, together with bio-medical sensors and test surveillance equipment It is suitable for use in laboratory and road conditions.

Time synchronized data recording of precisely timestamped data from all application relevant sensors, together with bio-medical sensors and test surveillance equipment It is suitable for use in laboratory and road conditions. -

Realistic data playback of relevant sensory data recordings and direct data injection into real HW under test HIL data injection enables comfortable development with test data and thorough test and validation with golden reference data sets.

Realistic data playback of relevant sensory data recordings and direct data injection into real HW under test HIL data injection enables comfortable development with test data and thorough test and validation with golden reference data sets. -

Synthetic HIL data injection that uses pre-recorded or real-time generated 3D synthetic models of drivers. By using synthetic data, companies can quickly bridge the gap in developing complete training data sets, i.e. based on gender, body type, race and other requirements from AI engineers. Simulated 3D models offer absolute positioning precision within the 3D space, which is very beneficial at specific development and test stages.

Synthetic HIL data injection that uses pre-recorded or real-time generated 3D synthetic models of drivers. By using synthetic data, companies can quickly bridge the gap in developing complete training data sets, i.e. based on gender, body type, race and other requirements from AI engineers. Simulated 3D models offer absolute positioning precision within the 3D space, which is very beneficial at specific development and test stages. -

Automated test-benching is possible through sophisticated scripting logiRECORDER users can utilize the logiRECORDER Software Development Kit (SDK) to build up completely automated test-benches that work 24/7 and save on time and costs.

Automated test-benching is possible through sophisticated scripting logiRECORDER users can utilize the logiRECORDER Software Development Kit (SDK) to build up completely automated test-benches that work 24/7 and save on time and costs.